Resource recovery from wastewater

A problem as an opportunity

For most of us, wastewater is something we don’t like to think about too much. It’s down the sewer: out of smelling range, out of mind. But believe it or not, “there’s gold in them thar sewers” – or at least some other valuable resources. And the push is on at the CRC for Water Sensitive Cities (CRCWSC) to recover them, with promising results for both the water and agricultural industries.

For most of us, wastewater is something we don’t like to think about too much. It’s down the sewer: out of smelling range, out of mind. But believe it or not, “there’s gold in them thar sewers” – or at least some other valuable resources. And the push is on at the CRC for Water Sensitive Cities (CRCWSC) to recover them, with promising results for both the water and agricultural industries.

That wastewater contains useful nutrients is nothing new. But it’s only recently that researchers like the University of Queensland’s Associate Professor Damien Batstone, leader of CRCWSC’s Sub-project C2.1 (Resource recovery from wastewater), have been developing the technology to recover them. It’s a classic case of seeing a problem as an opportunity. The problem with wastewater is that nutrients in it (nitrogen, phosphorus, and potassium) promote the growth of microbes in waterways, often causing toxic blooms. So traditional sludge treatment has focused on removing nutrients or rendering them biologically unavailable.

But these same nutrients are major components of agricultural fertilisers. Nitrogen, phosphorus, and potassium are critical for plant growth. Considerable amounts of energy are used to fix atmospheric nitrogen into a form that can be used by plants. Meanwhile, wastewater treatment expends energy as it releases nitrogen back to the atmosphere: in essence, spending valuable resources to destroy resources. Phosphate is vital for agriculture, given Australia’s depleted soils. And with declining global reserves, the cost of this non-renewable resource is increasing. Traditional wastewater treatment removes phosphorus – either by chemical precipitation (consuming resources, again) or biological accumulation – and discards it as waste sludge.

Professor Zhiguo Yuan, leader of the CRCWSC’s Program C (Future Technologies), works with Damien Batstone at the University of Queensland’s Advanced Water Management Centre. He explained that the Program’s research is focused on cities becoming more resource-independent, especially through more efficient use and reuse of water. A paradigm shift in the past two years has led to a greater emphasis on recovering resources from the waste stream. With world-class expertise in this field, Damien was an obvious choice to lead the resource-recovery component of this research.

A concentrated solution

While phosphorus recovery has been around for a decade, recovery of nitrogen and potassium is an emerging area. The question, particularly with nitrogen, has been not so much whether to do it but how. The method Damien is developing involves three steps: partition, release, recovery.

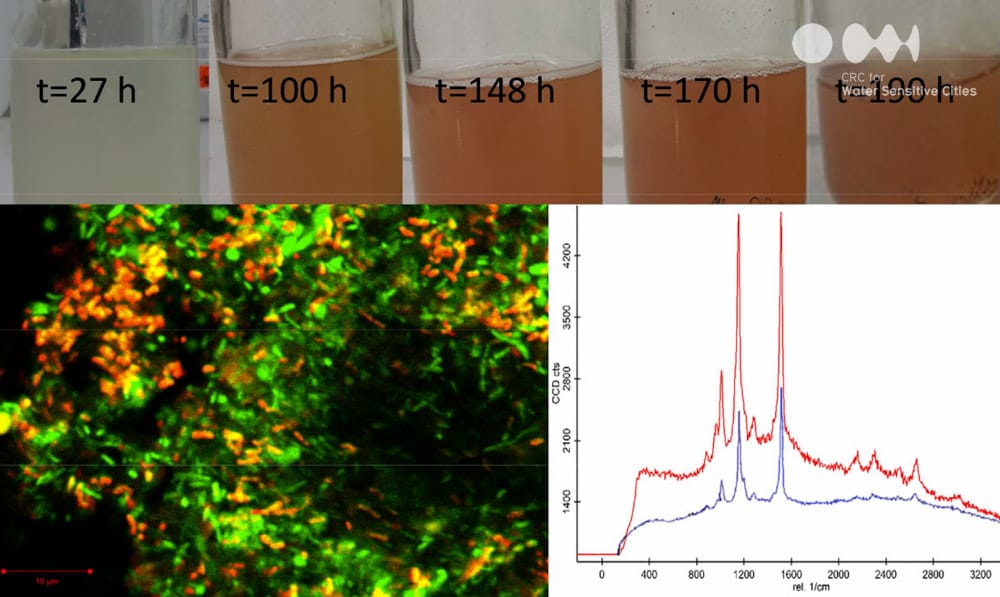

The partition phase removes and concentrates nutrients from the wastewater. It makes use of bacteria and algae that grow through feeding on nitrogen, phosphorus, potassium, and carbon. When assimilated by these microbes, the nutrients move from liquid to solid form. Solids are separated from the water (now depleted of dissolved nutrients) by filtration through a membrane, and are then further concentrated mechanically.

To extract the nutrients, they must first be released back into a liquid stream. This is done by anaerobic digestion, producing a nutrient-rich brew one hundred times more concentrated than the original wastewater. Various chemical and physical methods are then used to recover the nutrients. Energy is also recaptured, in the methane gas that is generated from anaerobic digestion.

The nutrients have been further processed into a fertiliser that compares favourably with current commercial products. Wheat being a bulk consumer of fertiliser in Australia, this research has also been supported by the grains industry. So far, it has functioned well as a direct replacement for mono-ammonium phosphate, in terms of both nutrient concentration and application procedure.

Energy efficiency

This all sounds very promising; so it’s no surprise that the Victorian water industry is also interested. Along with the CRCWSC and The University of Queensland, Melbourne’s City West Water has become a sponsor of the research – through the Smart Water Fund, an initiative of the Victorian water industry to increase innovation and collaboration. City West Water’s Sean Hanrahan sees the potential for significant revenue opportunities. Given that humans pass 20% of the mineral phosphorus applied in agriculture, recovering this would recycle a significant volume of the nutrient, potentially at a cost below the current A$3000 per tonne.

Combined with a smaller energy footprint for bioavailable nitrogen than the standard industrial process (and substantial energy savings in wastewater treatment), this makes the project very exciting environmentally and economically.

Along with resource recovery, energy efficiency is a key driver for City West Water, which sees the potential of this research to help the water industry operate more sustainably and work towards carbon neutrality. Indeed, while activated sludge treatment requires energy for pumping and aeration because it uses aerobic microbes for nitrogen conversion, the partition-release-recover process uses anaerobic microbes; so it consumes far less energy. Furthermore, instead of wasting electricity to burn off the organic compounds, the anaerobic digestion process converts them to methane gas, which is recovered for generating electricity. This electricity is put to work in the system, making it energy-neutral. The process may even produce a small net energy gain.

Another advantage of partition-release-recover over traditional treatment is the small volume of sludge remaining at the end of the process, which means less waste for disposal, reduced transport costs, and decreased risk of transport-related incidents.

The way of the future?

Positive developments indeed; but further refinements are needed before the technology is ready to go. The partition phase is the biggest challenge. Much work has been done on manipulating conditions to favour the growth of organisms that suck up the nutrients; the next stage is to turn this into practical technology. A pilot processing plant will be built this year, next to a larger conventional treatment plant at Brisbane’s Luggage Point Advanced Water Treatment Plant.

A key step over the next two to five years will be to fit the technology into existing conventional infrastructure; for example, replacing nutrient destruction techniques with nutrient recovery. Within five years, it’s expected that smaller-scale processing plants could be built using this technology. The system is designed to work as a drop-in replacement for existing treatment plants; so in the longer term, the technology could be expected to roll out over decades replacing activated sludge treatment as new plants are built and ageing infrastructure is replaced.

The prospect of such widespread improvements in the efficiency of resource use is an exciting outcome of this innovative CRCWSC research, set to benefit not only the water and agricultural industries but also the cities of the future.

Nicola Dunnicliff-Wells for the Mind Your Way team