Resource recovery from wastewater

Contact

Insight:

A new wastewater treatment technology can generate products for Australia’s $5 billion fertiliser market and $1 billion aquaculture market

The drivers

Desire to re-examine current methods of treating wastewater to extract valuable nutrients and save on energy costs

- Increased world population, population shifts to megacities and the vulnerability of conventional crop production to climate change prompted a re-examination of current methods of treating wastewater.

- Current wastewater treatment technologies do not harvest useful nutrients (phosphorous, nitrogen, potassium) from wastewater, and are very resource intensive. They also impose a financial cost on the community, who do not benefit financially from the treatment process.

- Industry and researchers recognised the need to recover nitrogen and other resources from wastewater. Recovering these valuable nutrients could offset the environmental and financial costs of energy intensive industrial nitrogen fixation and mined phosphorous.

- Animal production wastewater treatment and animal feed production have both become more profitable in recent years. This is particularly true of aquaculture, which worldwide has grown on average by 8% each year since 1961, and now supplies 47% of all food fish.

- Aquaculture is the fastest growing animal food production industry, now producing 50% of all food fish. However, aquaculture feeds depend on fishmeal derived from capture fisheries, which must be reduced for continued sustainable growth.

The innovations

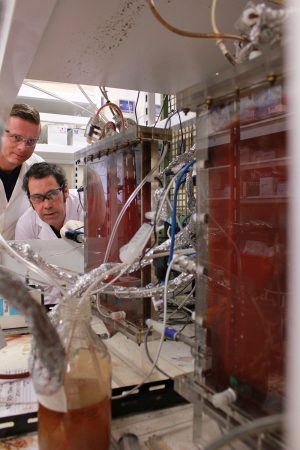

Creation of a novel wastewater treatment platform that uses purple phototrophic bacteria (PPB) to simultaneously remove organic material, nitrogen and phosphorous, without destroying these valuable nutrients

- Purple phototrophic biofilms—These films are attached to submerged infrared illuminated surfaces. Biofilms grow extremely quickly and outcompete other organisms which may otherwise grow on the surface. This process enables a consistent, easily harvestable material stream.

- Light-sensitive bacteria extracts nutrients from wastewater (treated sewage), converting them into solids—These nutrients (potassium, phosphorous and nitrogen) are highly valued as fertilisers by the agricultural sector, and currently are in short supply. The project scope expanded to allow for the production of byproducts, particularly single cell proteins, which can then be used for feed or feed additives in aquaculture.

- Pilot units of varying sizes, from 160mL to 1000L—Much of the original concept development was done at very small scale, and then scaled up to produce enough biomass for a large scale barramundi trial. It has been trialled with natural lighting at piggeries and chicken processors.

- Pilot units treating a variety of wastewaters—The project has been trialled using domestic wastewater (both fresh and saline water), as well as agri-industrial streams (such as pig manure, poultry, red meat and dairy processing effluents).

Project stats

Location

Brisbane, Queensland, Australia

Dates

January 2020

Participants

Contact

The outcomes

Outcome one

Outcome one

-

The PPB treatment process meets or exceeds the technical performance capability of existing technologies, but in a single stage bioreactor. Via this project, it became clear that the correct balance of organics and nitrogen was a factor, so the project was reorientated to resource production, rather than domestic wastewater treatment.

Outcome two

Outcome two

- The treatment process is cost neutral or positive, when value in the product can be realised as organic fertiliser or animal feeds.

Outcome three

Outcome three

-

This new treatment process also has some aesthetic benefits. Wastewater treatment can generate methane, carbon dioxide and odours. By contrast, the PPB process produces almost no odours or greenhouse gas emissions, and the biomass is a purple colour, rather than the usual brown.

Outcome four

Outcome four

-

The complete capture of nutrients allows for societal recycling of nitrogen. Currently from fertiliser factory to plate, only approximately 16% of the nitrogen produced ends up available for human consumption. The PPB process can close this balance and completely capture nutrients, particularly from agricultural sources.

Outcome five

Outcome five

-

PPB efficiently yield biomass from wastewater with high product homogeneity and a relatively high protein fraction, making it a useful ingredient for fish feed.

Interested in this solution?

We partner with small and large companies, government and industry in Australia and around the world.

Comments